Abstract:

Since the finished quality of every layout project depends on a successful combination of products, processes and tools, it is essential to select each of these carefully...Show MoreMetadata

First Page of the Article

Abstract:

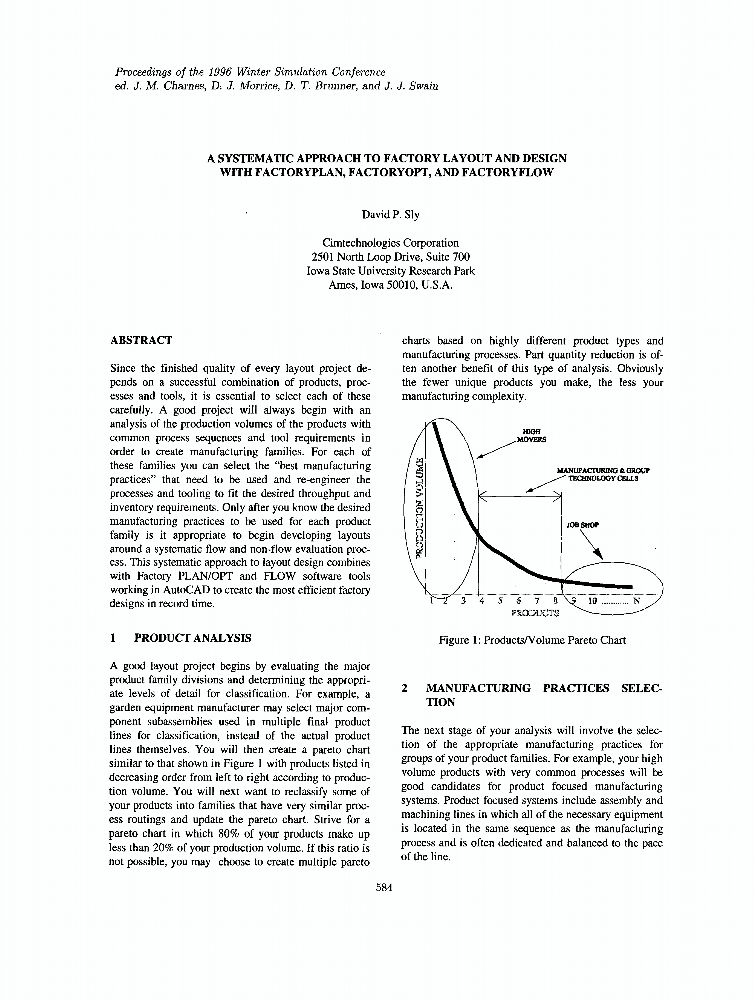

Since the finished quality of every layout project depends on a successful combination of products, processes and tools, it is essential to select each of these carefully. A good project will always begin with an analysis of the production volumes of the products with common process sequences and tool requirements in order to create manufacturing families. For each of these families you can select the "best manufacturing practices" that need to be used and re-engineer the processes and tooling to fit the desired throughput and inventory requirements. Only after you know the desired manufacturing practices to be used for each product family is it appropriate to begin developing layouts around a systematic flow and non-flow evaluation process. This systematic approach to layout design combines with Factory PLAN/OPT and FLOW software tools working in AutoCAD to create the most efficient factory designs in record time.

Published in: Proceedings Winter Simulation Conference

Date of Conference: 08-11 December 1996

Date Added to IEEE Xplore: 06 August 2002

Print ISBN:0-7803-3383-7

Conference Location: Coronado, CA, USA

First Page of the Article